In the search for new strategies to reduce the heavy rare earth (HRE) content, in particular of Dy/Tb, and also for reducing the manufacturing costs of sintered NdFeB magnets, some procedures have proved themselves to be suitable from a technical point of view.

The two-powder method enables fixing the HRE elements in their grain boundary area and contributes to the increase of HcJ.

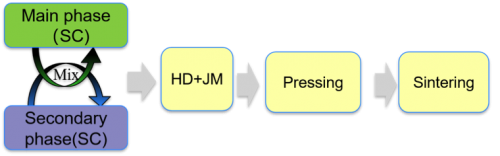

In this procedure, two types of powder are mixed, with one type of powder containing no or almost no HRE elements. During the sintering process, the HRE elements from the HRE powder are diffused into the originally HRE-free powder.

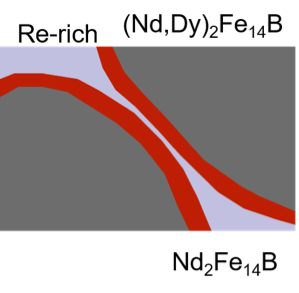

With a well-designed alloy composition and sintering process, the heavy HRE elements predominately concentrate or agglomerate within the grain boundary area. This process is far more effective than using a homogeneous distribution of HRE elements.

In this way it is possible to achieve a higher HcJ, with the same concentration of HRE, or respectively reduce the expensive HRE elements.

In 2018, Yunsheng produced more than 2000 metric tons of blocks using this technology.